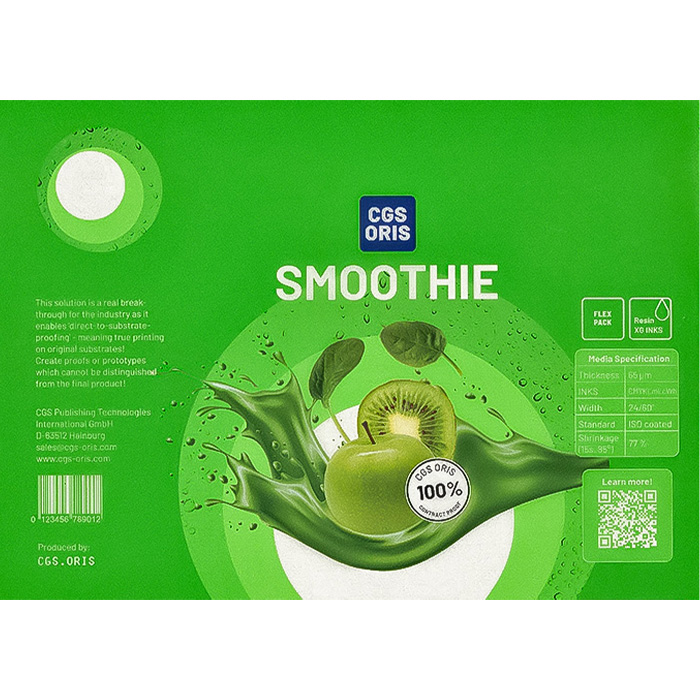

Ultimate Proofing Solution for Packaging

Proof on final substrates

Looks and feels exactly like the final product

Covers Pantone Library

Heiner Mueller, Sales Director Packaging, at CGS ORIS

- Packaging proofs and mock-ups on original substrate

- Color-accurate simulation of the final product

- Efficient and cost-effective

- Easy to use, with seamless integration into existing environments and any other CGS ORIS applications

Improve communication with brand owners thanks to a true representation that looks & feels exactly like their final product. This breakthrough proofing solution is set to transform the way prepress houses and packaging converters produce packaging proofs for their brand owner customers.

Improve

Gain

Save

Real Substrate Proof: Revolutionizing Packaging Printing

Real Substrate Proof: The Power of Shrink Sleeve Printing

Real Substrate Proof: Mastering Metal Printing

Real Substrate Proof: Perfecting Carton Printing

Real Substrate Proof, available exclusively from CGS ORIS, is a truly revolutionary approach to creating proofs, samples and mock-ups for packaging using the final target substrate, an approach previously not possible. Traditional proofing involves the use of expensive, specialized substrates that lack the true final appearance of the package. Real Substrate Proof, part of the Flex Pack Solution developed jointly with Mutoh, includes:

- Mutoh VJ-628MP or VJ-1628MH printer

- A compact footprint that fits in even the most space-constrained operations

- Best-in-class print quality

- Exclusive water-based resin inks in CMYK plus orange, green, blue and white with good adhesion on almost any surface

- A huge color gamut covering 97% of Pantone colors

- Odorless

- High flexibility

Our multi-resin inks feature excellent adhesion and unique stretching and shrinking properties, enabling printing directly to shrink sleeves and other thin films as well as corrugated boards, metal, uncoated label stock, folding carton and more.

Printing directly to shrink sleeves offers a unique solution whereby brand owners can shrink the film onto the target packaging to validate accurate distortion of the artwork in advance of production. This is not possible with traditional proofing and prototyping solutions.

Packaging proofs made perfect!

For more information, get in touch with our sales team!

They are glad to answer all your questions and provide you an individual sample.

PRODUCT REGISTRY

WITH A FEW CLICKS

REMOTE MAINTENANCE

SUPPORT THE EASIEST WAY

QUESTIONS?

PLEASE GET IN TOUCH!